MotoMaker

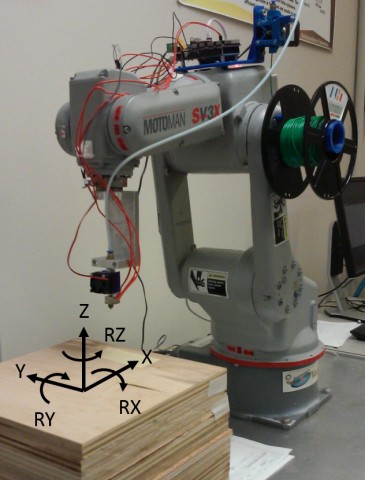

Robot Arm Platform for Additive Manufacturing (Ismayuzri, Larochelle)

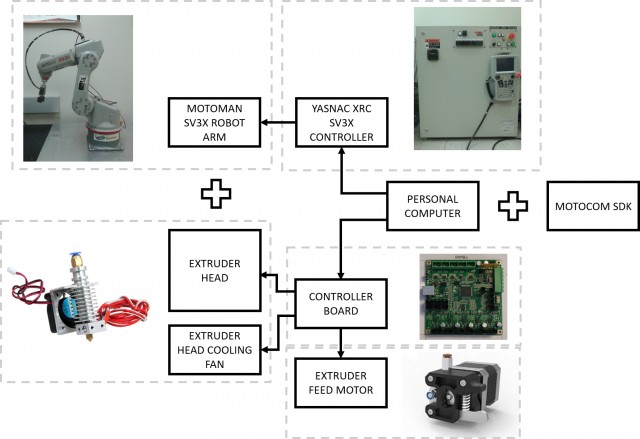

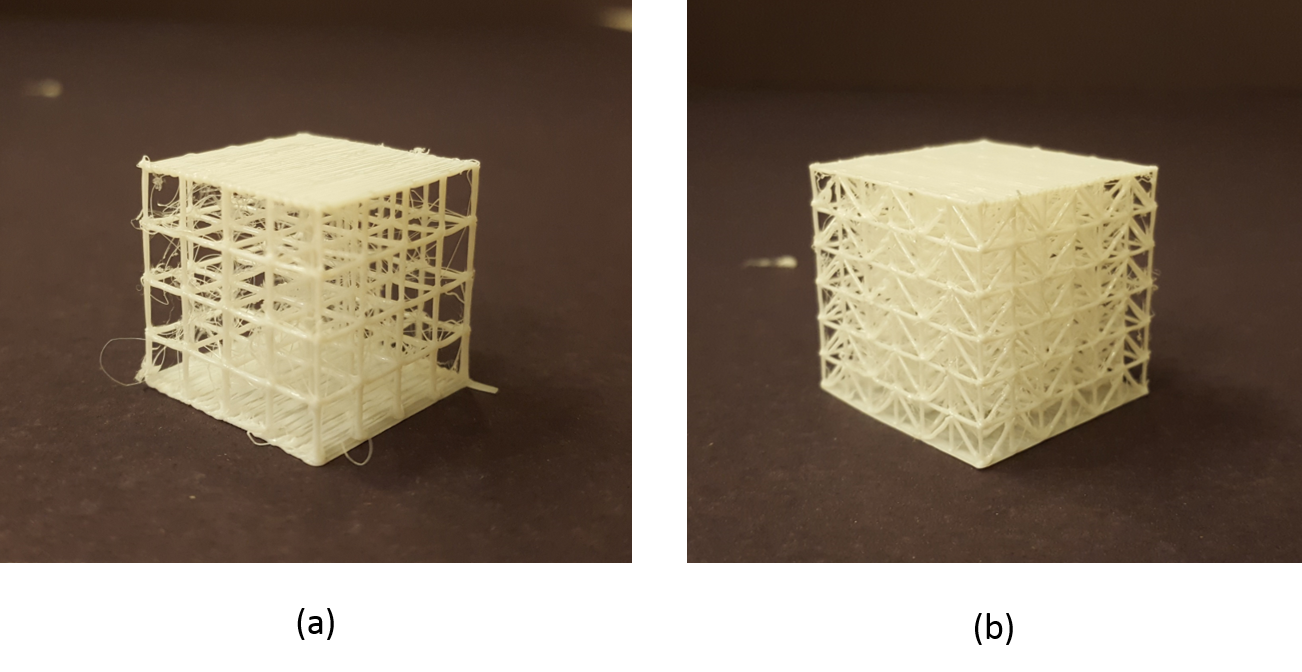

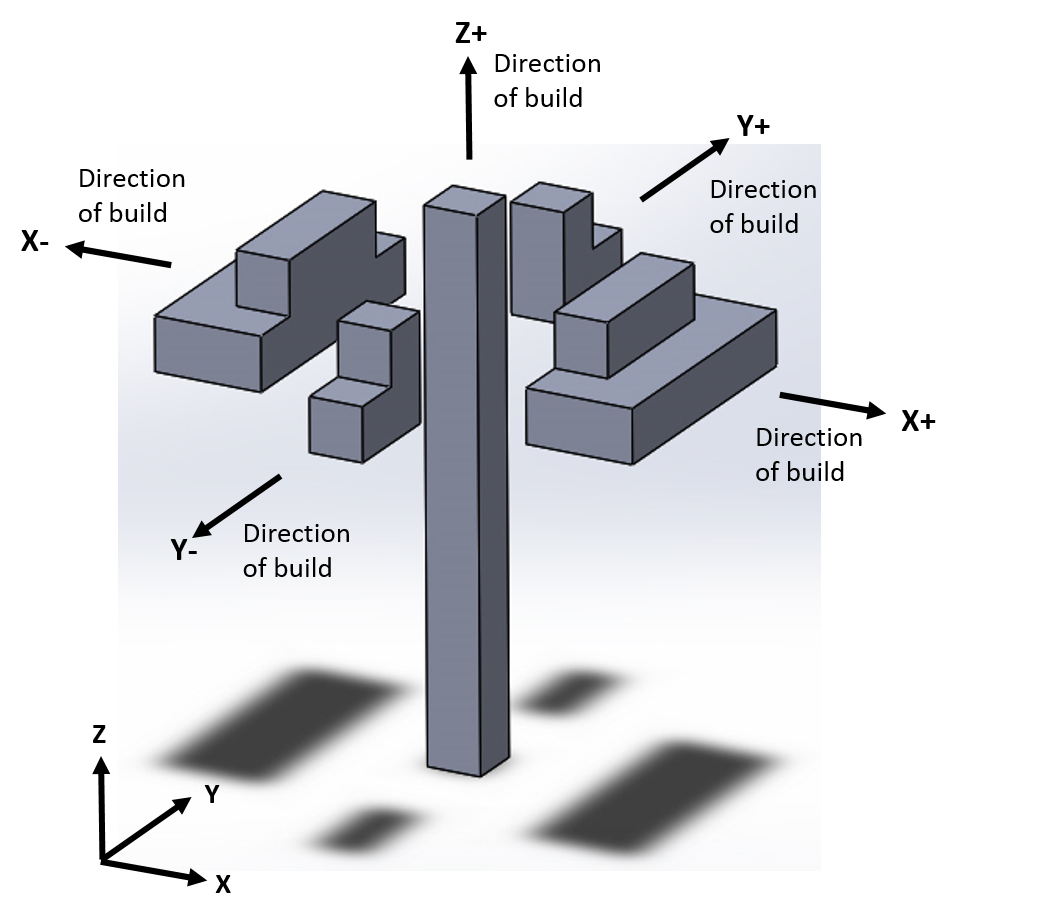

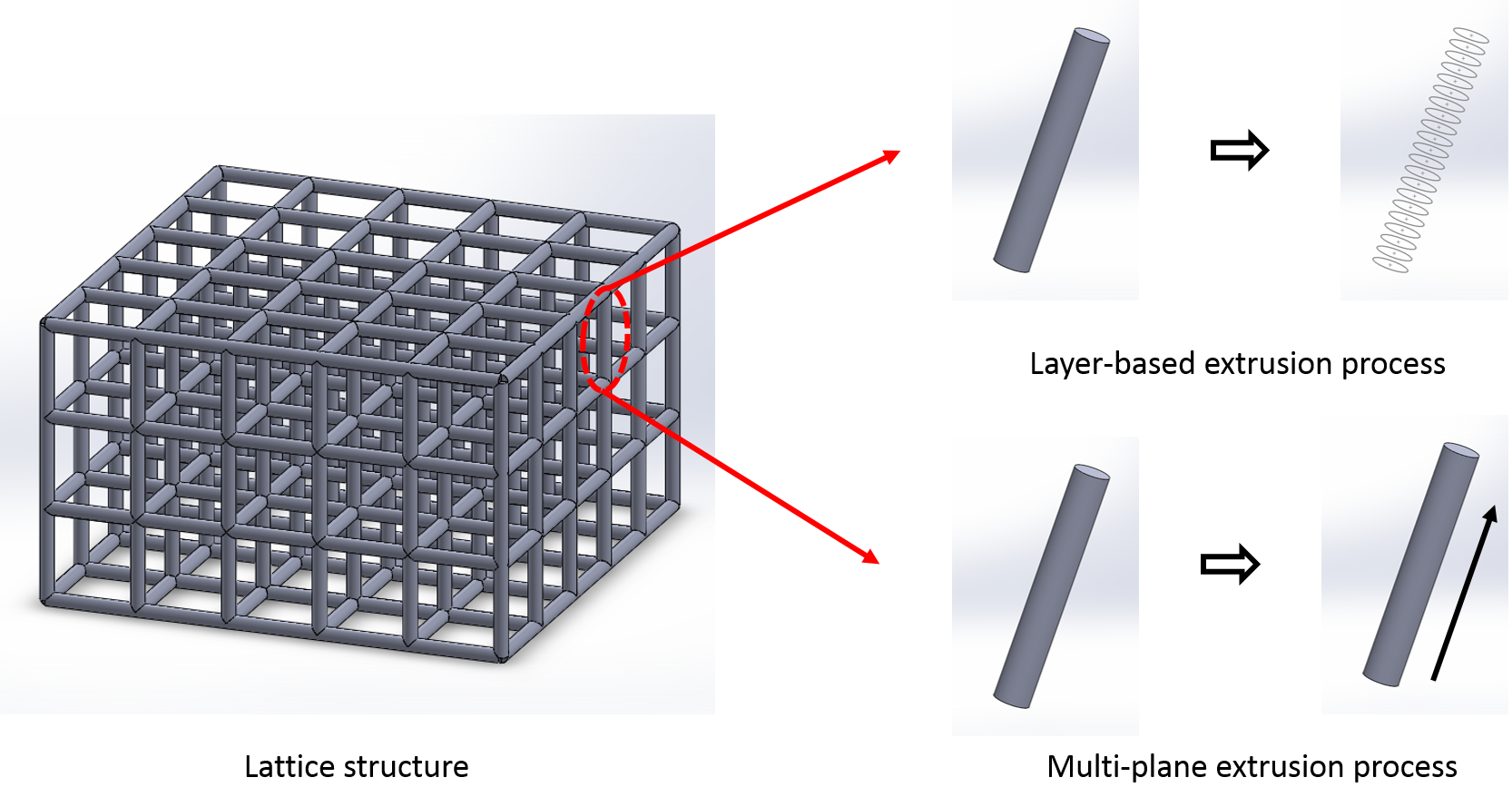

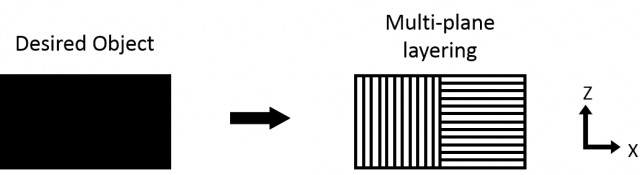

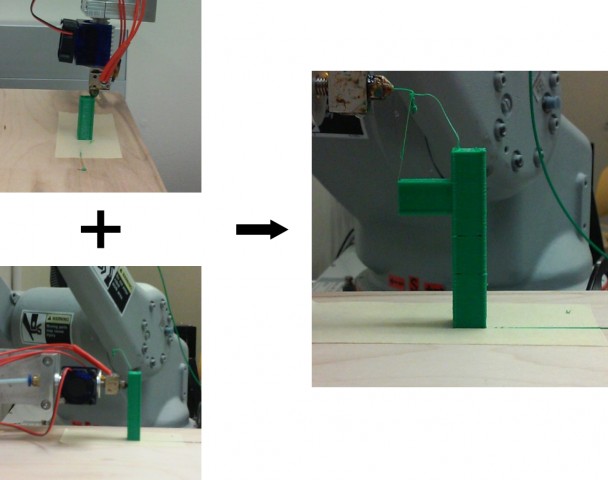

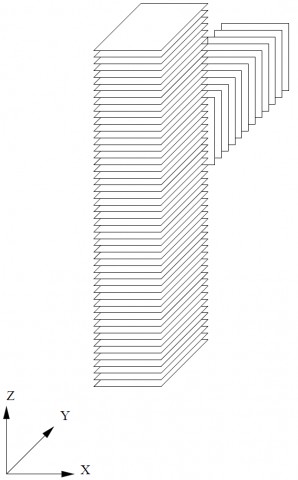

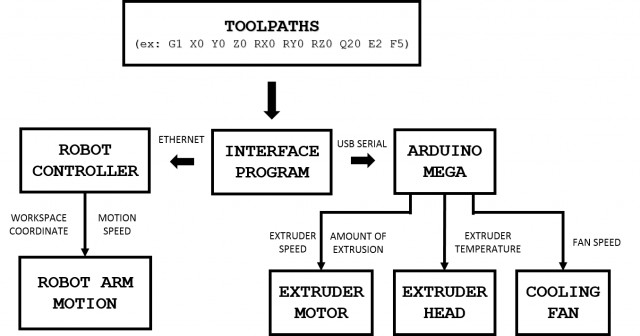

This research presents a concept of using a robot arm as a platform for additive manufacturing. The research being explored is the integration of existing additive manufacturing process technologies with an industrial robot arm to create a 3D printer with a multi-plane layering capability. A conventional 3D printer utilizes horizontal plane layerings to produce a 3D printed part. However, there are drawbacks associated with horizontal plane layering motions, e.g. the support material needed to print an overhang structure and the material property of the printed part is based on the geometric features during additive manufacturing process. In order to enhance the current capability of conventional 3D printing an industrial robot arm platform is proposed for additive manufacturing. This integration combines fused deposition modeling techniques using an extruder head that is typically used in 3D printing and a 6 degree of freedom robot arm. The integration of the robot arm and extruder enables multi-plane toolpath motions to be utilized in the production of 3D printed parts. With the multi-plane toolpath motions in 3D printing, exploration of new toolpath motions that hopes to improve the mechanical properties of the printed part, fabrication time to produce the part, and material usage with the multi-plane extrusion process.