SFB Designer

Web-based Computer-Aided Design & Manufacturing of Spherical Mechanisms (Schuler, Ketchel, Larochelle)

SFB Designer is an enhanced web-based version of our SphinxCAM software. SphinxCAM is the world's first computer-aided

manufacturing(CAM) software for spherical four-bar mechanisms. These devices have proven to be useful for orienting parts however

their manufacture can be challenging. To date this challenge has limited their use in industrial and consumer applications. SFB

Designer was created to address this challenge and facilitate the design and use of spherical mechanisms. SFB Designer provides

designers a free, web-based, tool to layout the parts and view the assembled mechanism.

SFB Designer lets the user specify the

dimensions of a spherical mechanism and then Pro|E part and assembly drawings are automatically generated. These drawings can be

downloaded as Pro|E part and assembly files or in STEP, dxf, iges, and other formats for use with other CAD/CAM software packages.

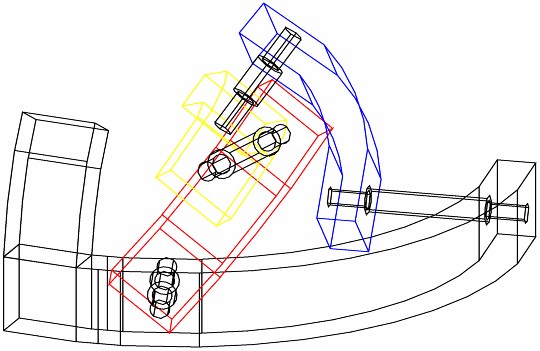

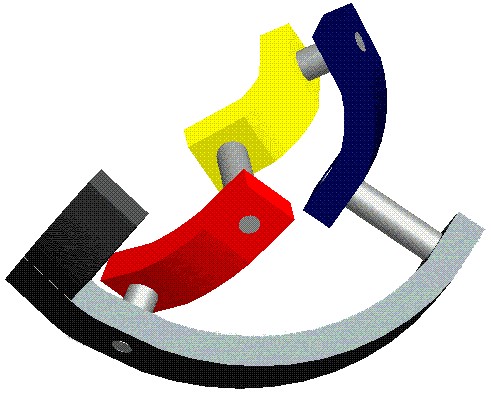

These files can be used to: visualize the three-dimensional assembly of the mechanism(ASM, JPG or TIF), perform static and dynamic

analyses(ASM), make a rapid-prototype (STL or STEP), or finally, to manufacture the mechanism using a CNC machine tool (IGES or

DXF). Moreover, tiff and jpg images of the assembled mechanism can be generated as well (see below). SFB Designer facilitates the

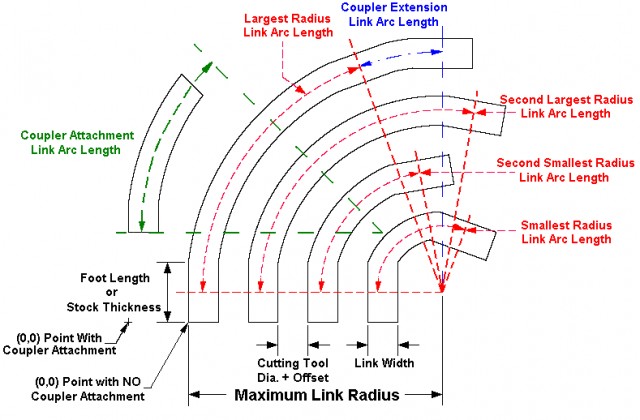

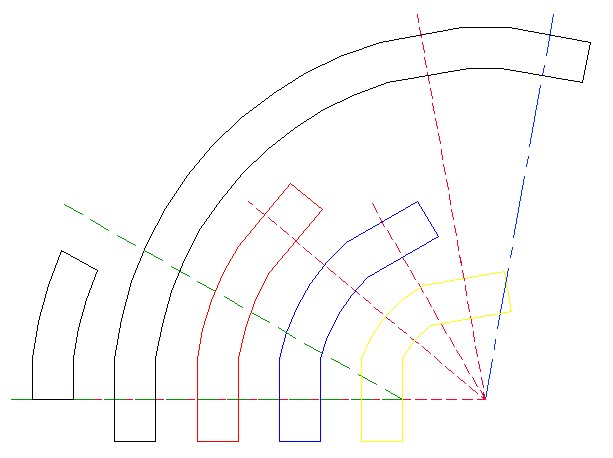

design, visualization, prototyping and manufacture of spherical four-bar mechanisms. SFB Designer lays out the mechanism's links

using circular arcs with feet at either end. The feet are designed to facilitate the accurate placement and orientation of the axes

and the use of bearings. The circular arcs are designed to allow the links to be spaced closely together. The result is a compact

mechanism that conserves material and has been layed out to facilitate precise arc lengths and accurate axes placement.

SFB Designer lays out the mechanism's links using circular arcs with feet at either end. The feet are designed to facilitate the accurate placement and orientation of the axes and the use of bearings. The circular arcs are designed to allow the links to be spaced closely together. The result is a compact mechanism that conserves material and has been layed out to facilitate precise arc lengths and accurate axes placement.